The Critical Role of Pool Surfacing

Overview

Swimming is a social activity. Guests, family members and friends can gather around a pool deck to relax, play, socialize or enjoy the sunshine. These areas are also hot spots for a list of health and safety risks. From the potential for slip and fall injuries to the spread of harmful microorganisms, resorts and hotels need to analyze how their material and design choices affect their ability to create a clean, safe environment for their guests to enjoy. It is with this commercial lens that we also approach residential installations, which are smaller in scale but offer the same challenges as large scale, commercial aquatic areas.

One of the most common – and most commonly overlooked – contributing factors to the health, safety, and enjoyment of guests in an aquatic environment is the pool surrounding surface material.

While many wouldn’t think to look beneath their feet to find five-star-worthy reasons to enjoy a swimming pool or spa, the quality and design of the pool ‘s surrounding areas and deck directly impact the safety, hygiene, and atmosphere of your aquatic areas.

We will define the critical role pool surround materials play in your aquatic area’s design and performance, as well as note the impact it has on your guests. This means carefully considering surfacing aspects like texture, hardness, color, coefficient of friction, chemical resistance, and other factors.

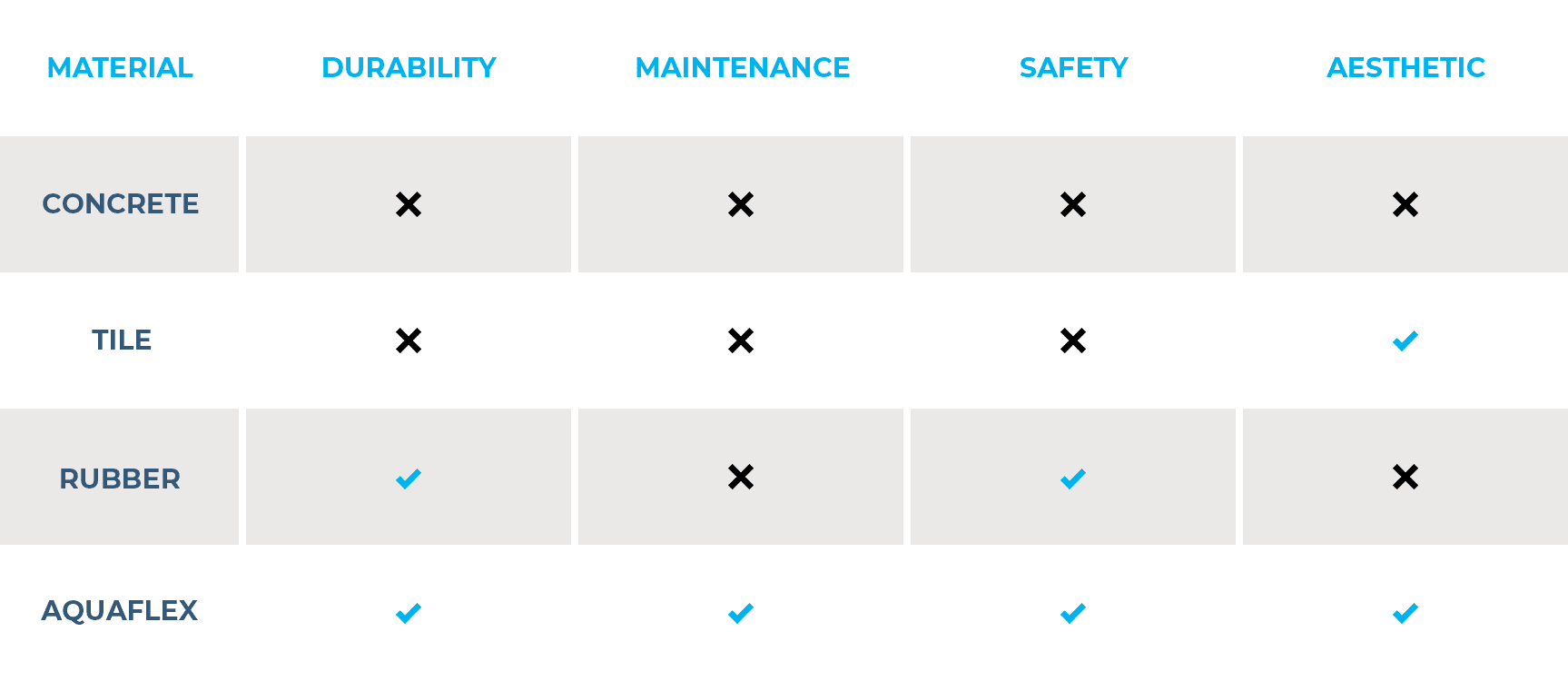

We will use four Key Factors as a lens for evaluation:

Durability

Cleanability / Maintenance

Safety

Aesthetics

Concrete / Pavers

Durability:

A concrete pool deck is strong, but rigid, and not necessarily durable on the surface. Natural factors (UV rays, temperature extremes), and everyday wear (pedestrian traffic, furniture use) play into inevitable cracking. Replacement is costly and bothersome.

Cleaning / Maintenance:

Safety:

Aesthetics:

Tile

Durability:

Cleaning / Maintenance:

Plastic interlocking is easy to rinse off, but water can get trapped under there and create an ideal place for mold and microorganisms to grow.

Safety:

Aesthetics:

Rubber (TPV/EPDM)

Cleaning / Maintenance:

In addition to cleaning and sanitizing the surface, a top sealer must be applied once in a while to keep the surface healthy. UV rays degrade polyurethane binders used to hold the rubber granules together during the initial install. Over time, these binders need to be replenished. If they are not, foot traffic can dislodge them, causing holes and cracks to appear, leading to an eventual system failure, where you have to replace the entire wear layer, or in some cases the base layer as well. Damaged areas are possible to repair, but due to the degradation of rubber from UV over time they are hard to match and patches can be noticeable and unsightly.

Safety:

Rubber is a skid-resistant solution because it is rubber-like, making it safer for children and adults. It also lessens impact from a fall. Darker colors absorb a bit more heat, but not as much as concrete or tile.

Aesthetics:

AquaFlex

Cleaning / Maintenance:

Safety:

Aesthetics: